Two-Phase Heat Transfer Technologies

Two-Phase Heat Transfer Technologies are the cornerstone of Novark's product line. There are numerous applications of two-phase fluid flow technologies in a variety of industries. They are also are a key component of most thermal management solutions. These technologies feature much higher thermal conductivity than solid copper and near-uniform temperature gradients, essential for effective thermal management devices. Two-Phase Heat Transfer Technologies are differentiated across their numerous applications by the structure of their wick, the working fluid used, and their shape.

The heat column is a hollow cylinder with a wick structure bonded to the interior surface. The evaporator section is the base of the column, and the walls and head of the column are the condenser section. Heat columns are paired with radial heat sinks that are attached to the heat column, providing a large surface area to dissipate the heat...

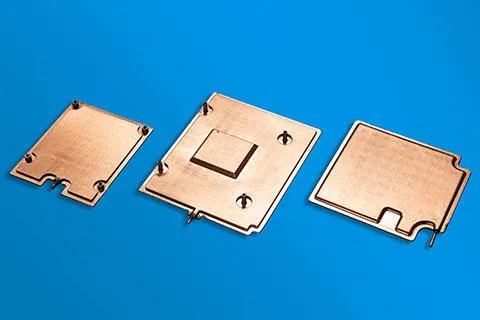

Vapor chambers are constructed from thin copper sheets that form a hollow chamber, the walls of which are lined with a sintered copper wire mesh or sintered copper powder. This forms a wick structure within the chamber. Additional columns of sintered copper powder are created in the wick structure for larger vapor chambers...

The ultra-thin heat pipe is formed either by flattening a thin-walled standard heat pipe with a wick structure in between. The wick structure is either a sintered copper powder section on one side of the heat pipe wall, or a copper wire mesh or fiber sintered in the center of the copper sheets...

The standard shape for most heat pipes is of a thin-walled tube with a wick structure. The main purpose of the standard heat pipe shape is to efficiently exchange heat from the heat source to the heat sink for dissipation, i.e. a “pipe” for heat...

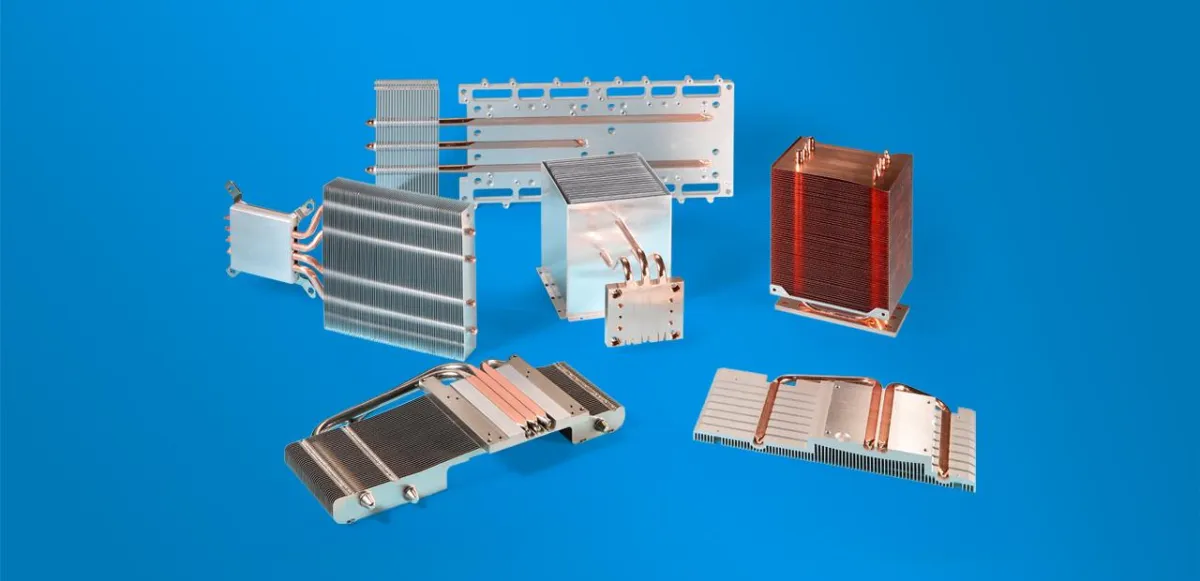

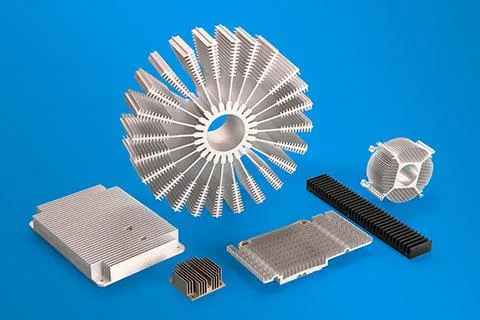

Heat Sinks

Heat sinks are an important component that helps move the flow of heat away from a hot device. They are the primary means of forced-convection heat dissipation in thermal management solutions, and are one of Novark's core products. Heat Sinks are differentiated by the method of manufacture of their fins, which define their cost and thermal performance. Several types of heat sinks that we manufacture which include skived heat sinks, folded fin heat sinks, extruded heat sinks and interlocking fin heat sinks.

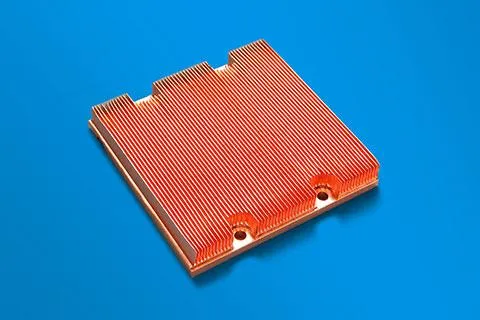

Skived heat sinks are manufactured by taking a solid block of material and slicing thin fins from the block, without removing the fin from the block. Every other fin sliced this way is removed, to create spacing between the fins. The resulting heat sink structure has higher fin density compared to extruded heat sinks and also features an uninterrupted flow path ...

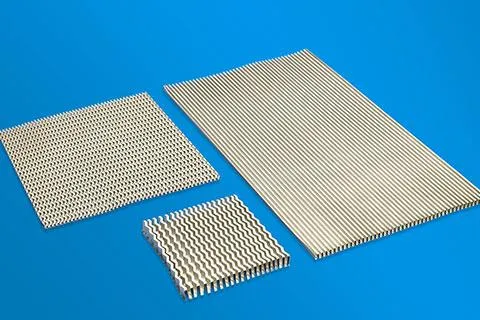

Folded fin heat sinks are created by folding a single sheet of metal multiple times to create a dense finned structure. This fin structure is then soldered, brazed, or bonded using thermal epoxy, to the heat sink base. This allows the base and fins to be of different materials, and allows a base with high thermal conductivity to be paired with lightweight fins...

Extruded heat sinks are made by first heating aluminum until it is soft, then pushing the softened metal through a machined die in the shape of the heat sink profile. Once the length of the heat sink has been reached, the extruded heat sink is cut from the die, and is then cooled and prepared for use....

Interlocking fins are manufactured by machining and stamping the fins from thin metal sheets. The fins are then interlocked into a structure that is either soldered or press-fit onto the thermal module. The fins can be manufactured to incorporate channels for the insertion of heat pipes, improving the thermal performance of the fin structure.

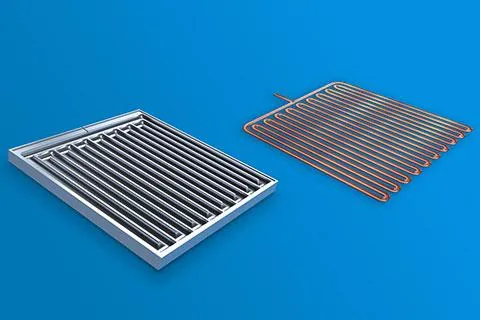

Cold Plates

Cold plates are the liquid-cooled heat dissipation method of choice, and are an important product in Novark's thermal solutions. Cold plates are defined by their method of manufacture, which defines their performance and application.

Vacuum-brazed cold plates are created by machining two metal plates with interior channels and fin structures (often folded fins and skived fins), which are then carefully sealed together inside a vacuum chamber. A filler metal with a lower melting point is melted into the joints of the cold plate via capillary action...

Tube-embedded cold plates are manufactured by press-fitting tubes into grooved plates, either partially or fully; this is called “dry bonding”. The tubes are then further machined to a specified flatness requirement to ensure good thermal contact with the heat source, and are further bonded to the cold plate by a thermal epoxy or a solder paste; this is called “wet bonding”.

Other Technologies

Novark Technologies pushes its design and manufacturing capabilities forward every year. The following technologies have been successfully prototyped at Novark Technologies, and Novark attempts new techniques and technologies on a consistent basis.

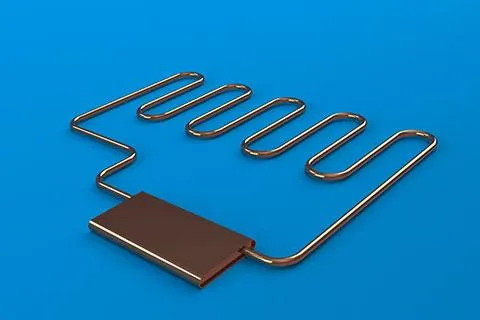

Pulsating heat pipes are made from a long capillary tube which is bent multiple times, or from a rectangular plate with capillary channels manufactured in it. The bends are placed at the evaporator and condenser areas of the heat pipe. This type of heat pipe does not require a wick structure to function...

Loop heat pipes are created from a specially-designed evaporator and a smooth tube that loops from one end of the evaporator to a compensation chamber that feeds into the other end of the evaporator. The smooth tubing is shaped into the condenser, and the evaporator is connected to the heat source...